Bought on the brand new Parlee Z-Zero GT highway bike? Curious the way it’s made? We swung by their Beverly, MA, headquarters to take a look at the brand new bike and get a better have a look at their all-new fork, their first ever designed and manufactured in home.

Whereas there, CEO John Harrison took us for a tour of your complete manufacturing facility and their Paint Lab, and we video’d the entire thing. Right here’s the total stroll by means of, adopted by extra pics and particulars on the bike and fork…

The video above exhibits their manufacturing facility and amenities. The pics beneath focus totally on the fork, however first a number of photographs of the brand new GT and the way its headtube compares to their different fashions.

Parlee’s present catalog consists of the RZ7 (aero highway bike, on left), the brand new Ouray all-road bike (middle, on pedestal), and the Taos gravel bike (again proper).

Within the foreground is the prior technology Z-Zero customized highway bike platform (darkish bike) and the brand new Z-Zero GT (white entrance finish). The GT successfully replaces the Z-Zero and will likely be out there in inventory and customized sizes.

This one is the twenty fifth Anniversary Version celebrating the life and work of founder Bob Parlee. Be aware the gold leaf inlays and detailed painted graphics. Click on any photograph to enlarge.

Some of the distinctive options of the brand new GT is the slim headtube that’s nonetheless in a position to conceal the brake hoses internally. From left to proper, these are the pinnacle tubes for:

Z-Zero GT

Prior Z-Zero

RZ7

Ouray

Be aware how slim the GT’s is, significantly on the prime. That is because of their new fork:

That is the completed product. Right here’s what it begins out as:

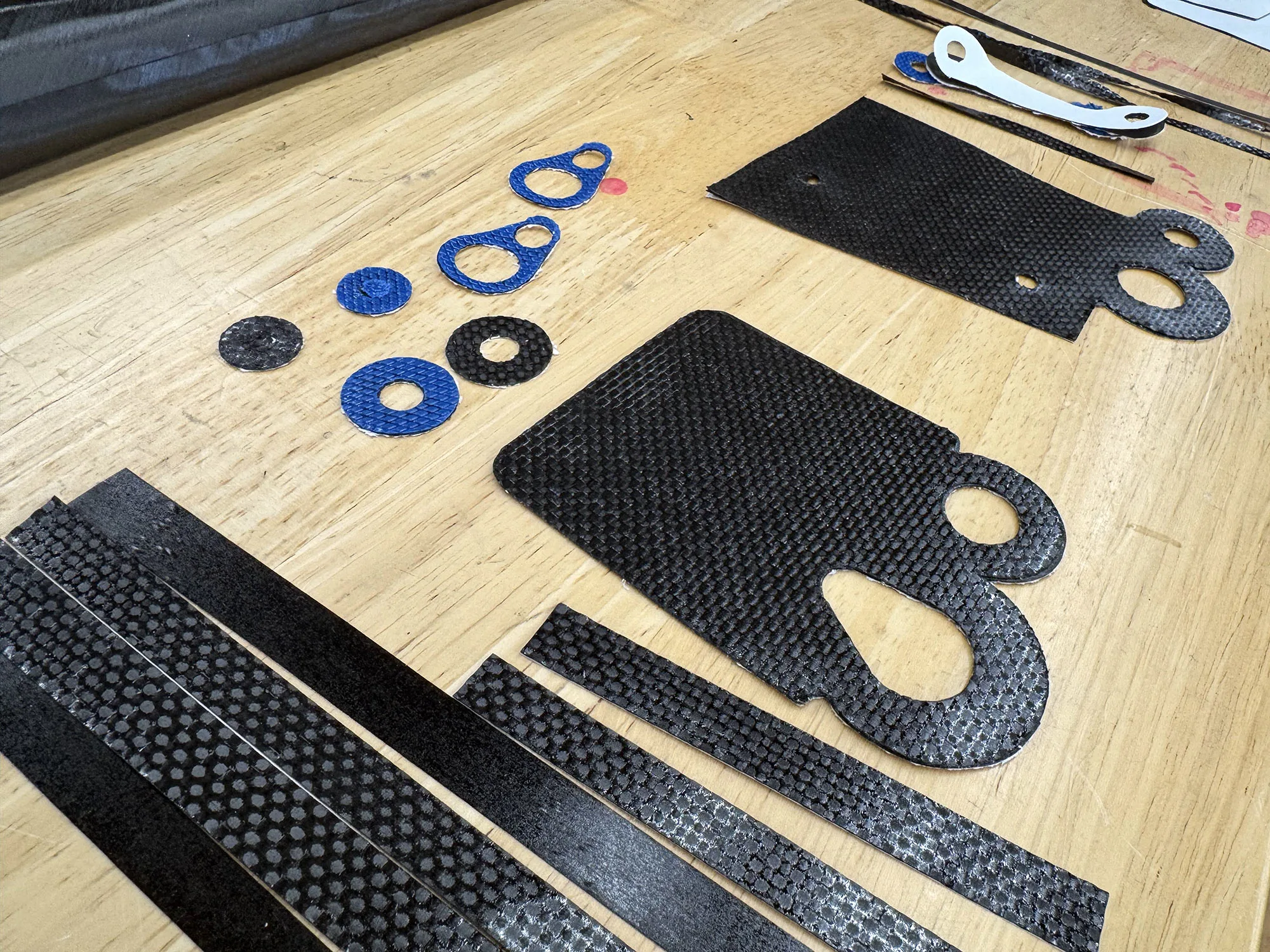

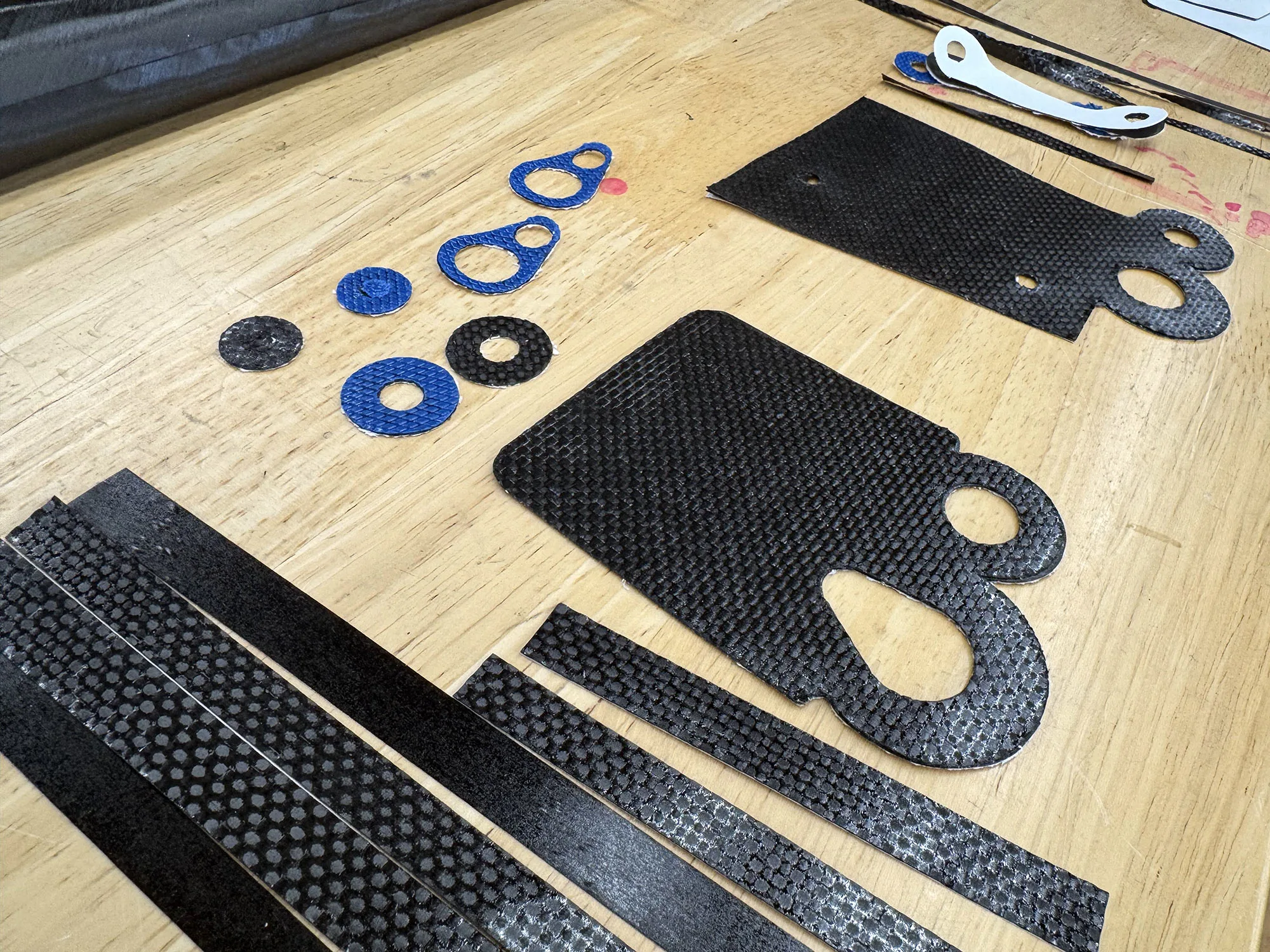

Parlee spent many months refining the layup, with tons of of distinctive items of unidirectional and woven carbon fiber used to make a single fork. The pic above exhibits simply a few of them.

Probably the most essential, and tough, half is the dropouts, the place a lot of the distinctive items are stacked and layered to make them robust sufficient whereas additionally delivering a snug trip.

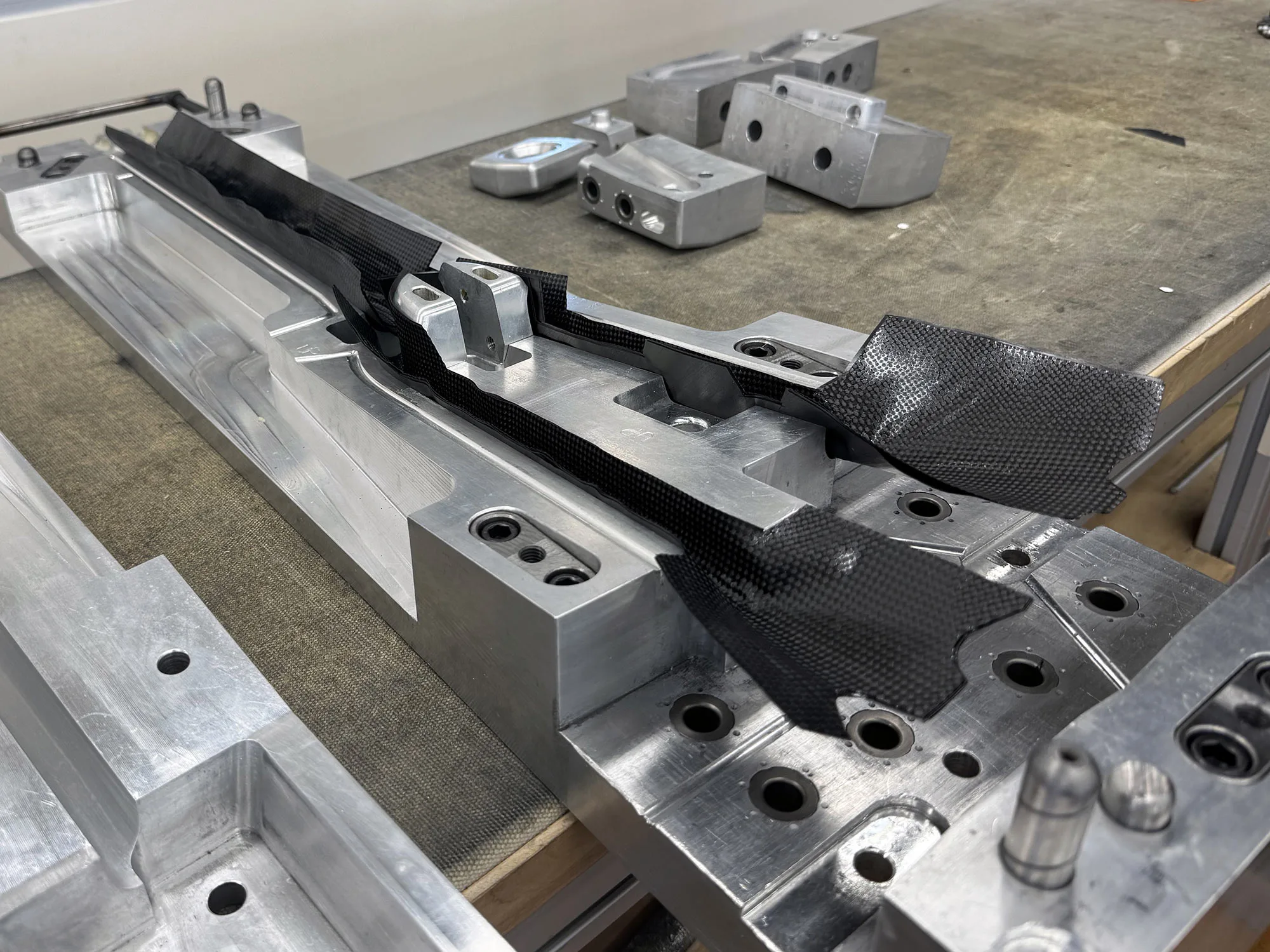

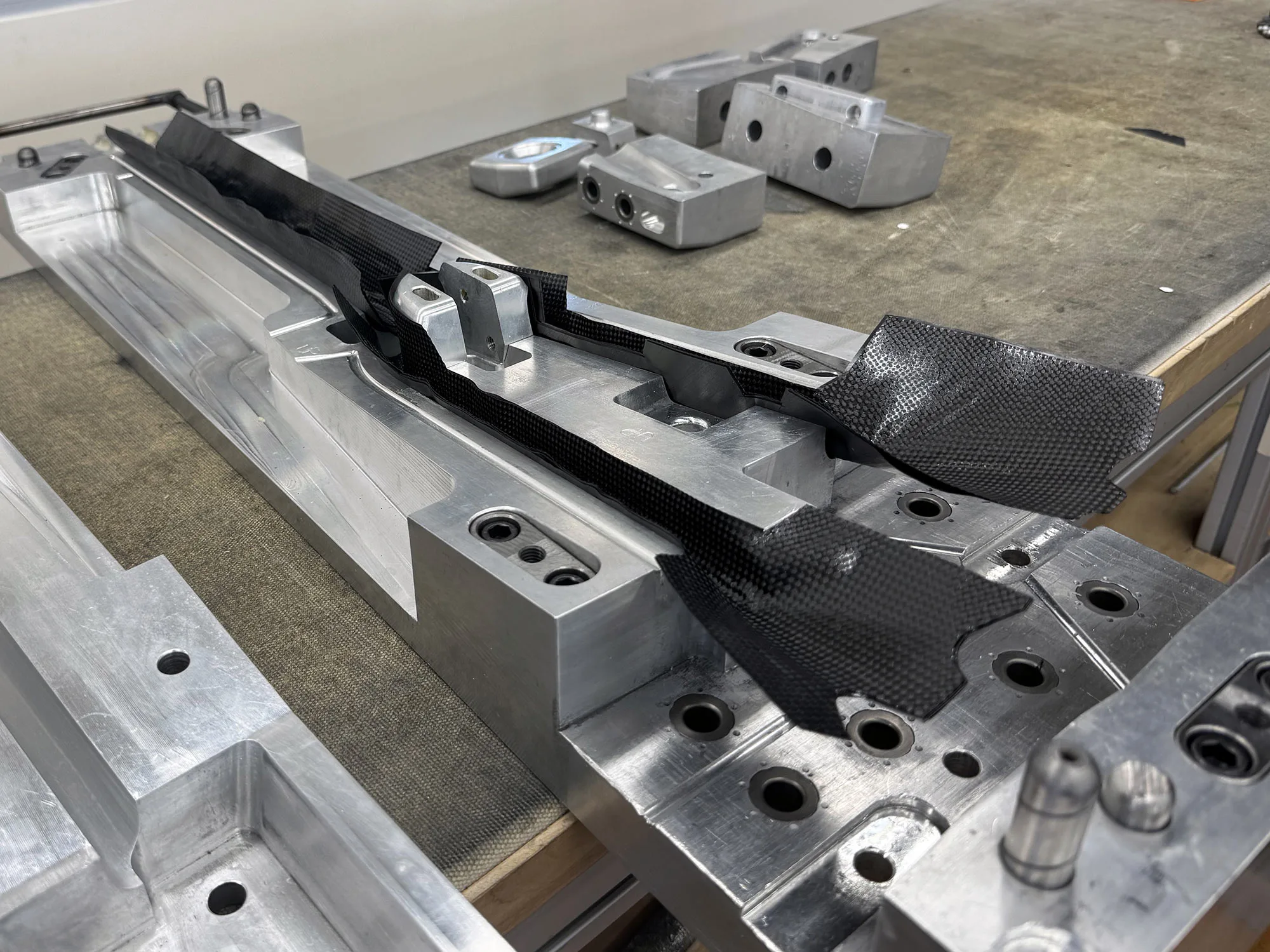

The outer layer is all UD, which is what provides the fork its easy end. They use onerous outer molds with expandable interior molds to press the carbon towards the steel throughout molding.

The forks come out almost completed…only a little bit of gentle sanding to take away the flashing (these little wisps you see on the crown) from resin because it’s pushed out of the seams and ports.

From right here, you possibly can simply wax the fork (and frames…they arrive out simply as clear) and depart that stunning carbon seen to all. That’s the lightest end, and also you received’t have to fret about scratches!

Probably the most distinctive characteristic of the fork is its D-shaped steerer, which permits them to run the brake hoses right into a standard-sized headset after which down into the body. A port on the base of the steerer feeds the entrance brake dampen into the leg to succeed in the caliper.

Throughout improvement, they examined totally different layups and despatched them to a German testing facility for impression, flex, and different traits. Examine the video to see a few of the early flaws they caught and also you’ll perceive why this course of is so necessary.

Additionally they lower them aside to see how the carbon layered and shaped throughout molding, permitting them to establish weak spots, folds, and different non-idea outcomes and work these out by refining materials placement and layering.

The tip result’s a motorcycle and fork they are saying rides higher than something they’ve ever made whereas staying true to their traditional Z-Zero aesthetic.

Hit up these hyperlinks to be taught extra concerning the new Z-Zero GT and the very cool, very costly twenty fifth Anniversary Version proven on this put up.

ParleeCycles.com