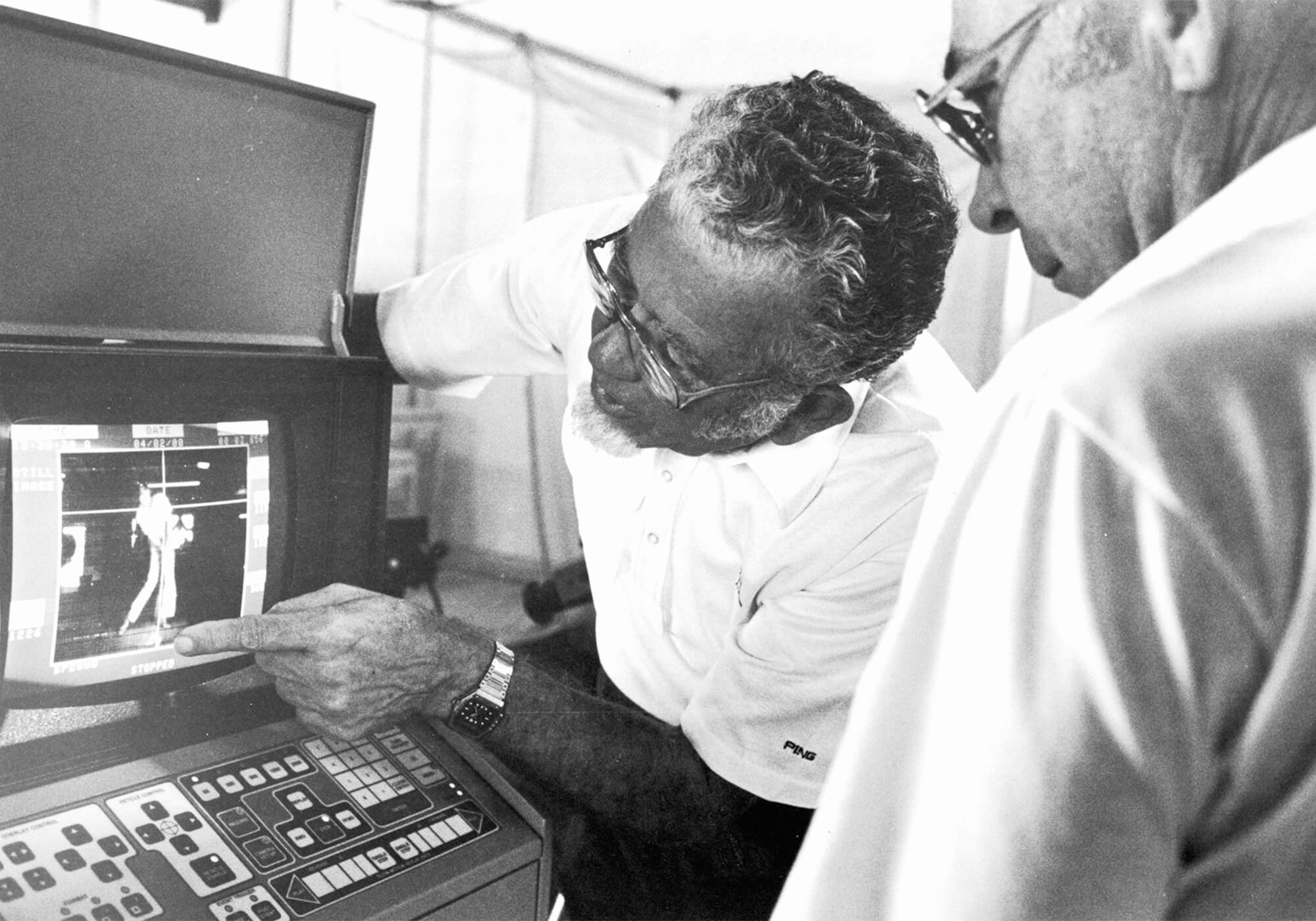

At PING, testing isn’t what occurs after design. Testing is design.Lengthy earlier than motion-capture rigs, ENZO, FOCAL, or perhaps a robotic named PING Man (enjoyable truth: the robotic is PING Man, the golfer in some variations of the PING emblem is Mr. PING), Karsten Solheim had a automobile, a desolate strip of highway in an undisclosed location within the Arizona desert, and a query.

The story goes like this: PING founder Karsten Solheim and his son Allan are driving by means of the desert at 100 mph. Karsten hangs out the passenger window holding a persimmon driver connected to a spring gauge to measure aerodynamic drag. No complicated pc simulations. No wind tunnel. Simply relentless curiosity, an concept, and simply the correct amount of recklessness.

That picture of Karsten within the desert remains to be intertwined within the firm’s DNA. If it may be examined, PING most likely has. If the end result doesn’t make sense, they’ll take a look at once more. And if the outcomes nonetheless don’t make sense, they’ll work to determine why after which take a look at some extra.

Tech that lasts

That dedication to testing isn’t any small a part of the explanation why PING’s most vital improvements aren’t developments; they’re fixtures. The Anser putter, Eye2 irons and G-series drivers had been engineered not for launch-day headlines however for endurance. Erik Henrikson, PING’s Director of Golf Science, says that’s by design: efficiency is one thing you construct on, not one thing you chase.“Our key forex is information,” he says. “And to realize information, it’s important to experiment, run exams and perceive what occurs.”That mindset produces what Henrikson calls sustainable efficiency—expertise that lasts as a result of it’s grounded in repeatable fact. As soon as PING finds a quantifiable benefit, it doesn’t abruptly transfer on to the subsequent massive concept; it continues to enhance the one it has.

The PING approach is probably not as attractive as annual barrage of “game-changing improvements” ceaselessly promised by an excellent little bit of the business however it helps clarify why improvements like turbulators, perimeter weighting and PING’s color-coded becoming system nonetheless matter many years after their debut in some circumstances.

Every era of PING product refines, not resets, the established basis.

One factor at a time

Arguably, these foundations are rooted in single-variable testing.

Tom Trueblood, Senior Check Engineer at PING, explains that each venture begins with a query, not a prototype. “You don’t begin with a membership and hope to study one thing. You begin with a query and construct a take a look at round it. We’re hyper-focused on single-variable testing. We wish to know what one factor does earlier than we ever discuss in regards to the system.”That “one factor” could possibly be one thing obvious to the golfer: turbulators, a brand new weighting construction or an up to date hosel adapter. Usually, it’s issues which might be all however invisible to the golfer: a paint components, bonding brokers or new groove geometry. The corporate runs roughly 1,400 exams a 12 months, of which about 15 p.c contain gamers. The remaining are constructed round what might feels like minutia to the remainder of us—plating sturdiness, bend life, even how new adhesives reply to Arizona’s summer time warmth.It’s tedious work and an excellent little bit of it doesn’t sound notably glamorous however it’s how PING turns curiosity into certainty (or near-certainty, anyway). Each measurable property is remoted, quantified and logged so the subsequent man doesn’t should guess.

When the items come collectively

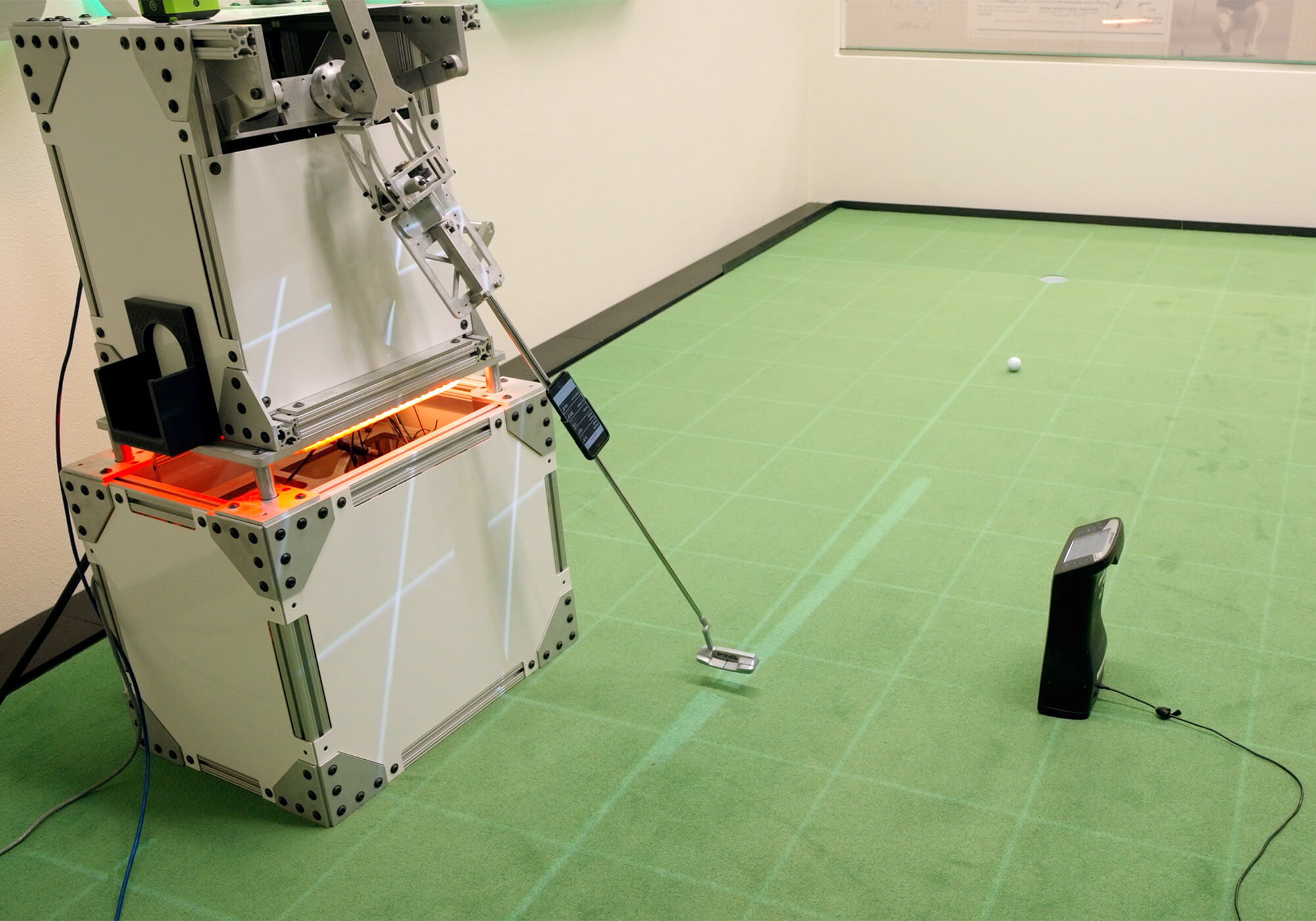

Golf golf equipment don’t exist in isolation. A brand new epoxy, for instance, is just one small piece of a bigger puzzle. In some unspecified time in the future, someone has to swing the membership. So, as soon as the single-variable work is completed, the crew turns to system-level experiments—how the sum whole of these single variables behaves when a human enters the chat.“Participant testing is probably the most seen,” Trueblood says. “It’s the place all the things comes collectively, the entire system. However it’s additionally the place it’s hardest to separate trigger and impact.”That’s the place PING’s layered testing mannequin shines. Participant testing tells engineers what occurred. PING’s proprietary FOCAL motion-capture exhibits what the participant did. PING Man may also help isolate the efficiency of the membership. By overlaying these knowledge streams, they will see precisely how human adaptation interacts with immutable bodily design.Henrikson factors to 1 instance. “If you transfer the CG again on a driver, you get extra lead. However gamers are likely to take that lead off—they de-loft the pinnacle extra at influence. The robotic exhibits one factor, the participant exhibits one other. You want each to know the total image.”

Defining “higher”

For PING, a product doesn’t come to market until it’s higher and the definition of “higher” is brutally easy: the brand new mannequin should outperform the final.“For many merchandise, the primary benchmark is the earlier era,” Henrikson says. “We’ve delayed launches. We’ve canceled merchandise as a result of we couldn’t beat the earlier era.”One instance from latest reminiscence is when PING pushed the launch of the G410 LST driver. On the time, some PING rivals thought the delay was a stunt that might permit the corporate to juice the market mid-season. Nonetheless, the reality was that its predecessor, the G400 LST, carried out so effectively that preliminary prototypes for brand spanking new mannequin couldn’t greatest the unique.

“All people’s sitting round going, ‘Did we create a unicorn?’” Henrikson remembers. “The 400 LST simply did one thing we didn’t absolutely perceive till the 430.”PING may’ve shipped the G410 anyway. They wouldn’t have been the primary golf firm to roll with what they’d. As an alternative, they stored working.

The choice most likely price a couple of million in short-term gross sales however inside PING’s firm partitions, higher has to imply one thing. If nothing else, the story serves as a reminder that at PING, innovation drives the calendar, not the opposite approach round.

And when it nonetheless isn’t higher …

As within the case of the G410 LS, generally testing doesn’t produce the decisive win that pc simulations recommend it ought to. When that occurs, PING digs deeper.All the things needs to be checked. Warmth remedies might not have been absolutely cooked, wall thicknesses (in a driver head there might be greater than 200 particular dimensions) can drift—there is no such thing as a scarcity of attainable suspects.

Have been the inputs right? Did the robotic ship the membership as supposed? Was there one thing else within the take a look at setting? In the end, is the setback a results of the design or the execution?

Henrikson says discovering these solutions is usually a “CSI Mission”—a forensic loop of simulation, prototype and validation the place no assumption goes unchallenged. Monitoring down the supply of small errors early within the design course of is how PING avoids making greater ones on retail cabinets. It’s a gradual course of, generally, however it’s additionally why PING hardly ever releases duds.

Constructed to final

One of many few assumptions PING makes is that golfers hold their golf equipment longer than the market needs them to. So sturdiness and longevity are at all times a part of the equation.

“We all know numerous gamers are four- to six-year drivers,” Trueblood says. “So we expect in these phrases. Longevity isn’t simply sturdiness. It’s efficiency that stays related.”

That’s a succinct approach of claiming PING doesn’t simply construct golf equipment to final bodily, it builds them with efficiency that stays related. Certain, the constructions should survive warmth, chilly, journey, and hundreds of swings (not all of them good), however the outcomes have to carry up, too.

Whereas the corporate is at all times chasing higher, it isn’t all for making your final buy out of date. A PING membership is constructed to carry out for years, not simply till the subsequent launch cycle. That’s the distinction between sturdiness and sustainable efficiency.

The trade-off: High quality versus efficiency

In testing and design, efficiency and high quality are generally opposing forces. Thinner faces can imply quicker ball speeds however in addition they improve the danger of cracks. A brand new end may be extra aesthetically pleasing however chips underneath stress. Even the best-performing materials can grow to be problematic if it’s too laborious to bend or too inconsistent to bond.

“High quality isn’t one thing you bolt on on the finish,” Trueblood says. “It’s a competing constraint you resolve for at each step.”

At PING, progress isn’t measured by how far they will push a CAD mannequin. It’s measured by how reliably the ultimate product performs in testing and in manufacturing. Generally the higher design isn’t the one which wins on a launch monitor, it’s the one which performs the identical approach each time, for years.

That steadiness extends past the participant. PING’s engineers know {that a} design that’s good on paper however not possible to construct isn’t a hit, it’s a bottleneck. Some alloys can push efficiency however make the bending course of bodily tougher on the construct crew, including actual fatigue over time. A membership needs to be quicker and stronger but in addition buildable. The individuals on the store ground are a part of the suggestions loop. If a course of provides pointless pressure or inconsistency, it will get redesigned.

PING’s physics-assisted AI

In an business the place AI is an more and more fashionable, though nonetheless considerably nebulously utilized, buzzword, PING prefers to advertise its HI (Human Intelligence).

That’s to not say it doesn’t have loads of computing horsepower however PING’s method to synthetic intelligence begins with established physics and its many years of accrued information. Henrikson explains that their fashions use actual swings from actual gamers as inputs. Every swing’s supply knowledge feeds into physics-based simulations that may run hundreds of digital exams earlier than the primary prototype is created.

“We will feed actual swings into our fashions and run hundreds of digital exams,” he says. “We will range CG, MOI, bulge and roll, COR—optimize for 30 actual swings—and see what occurs earlier than we ever minimize steel.”Fairly than letting algorithms invent golf golf equipment, PING’s course of makes use of many years of measured knowledge to information what these algorithms can do. The mathematics serves the physics, not the opposite approach round. The aim, as Henrikson places it, is to know, to not outsource curiosity.

The testing pool

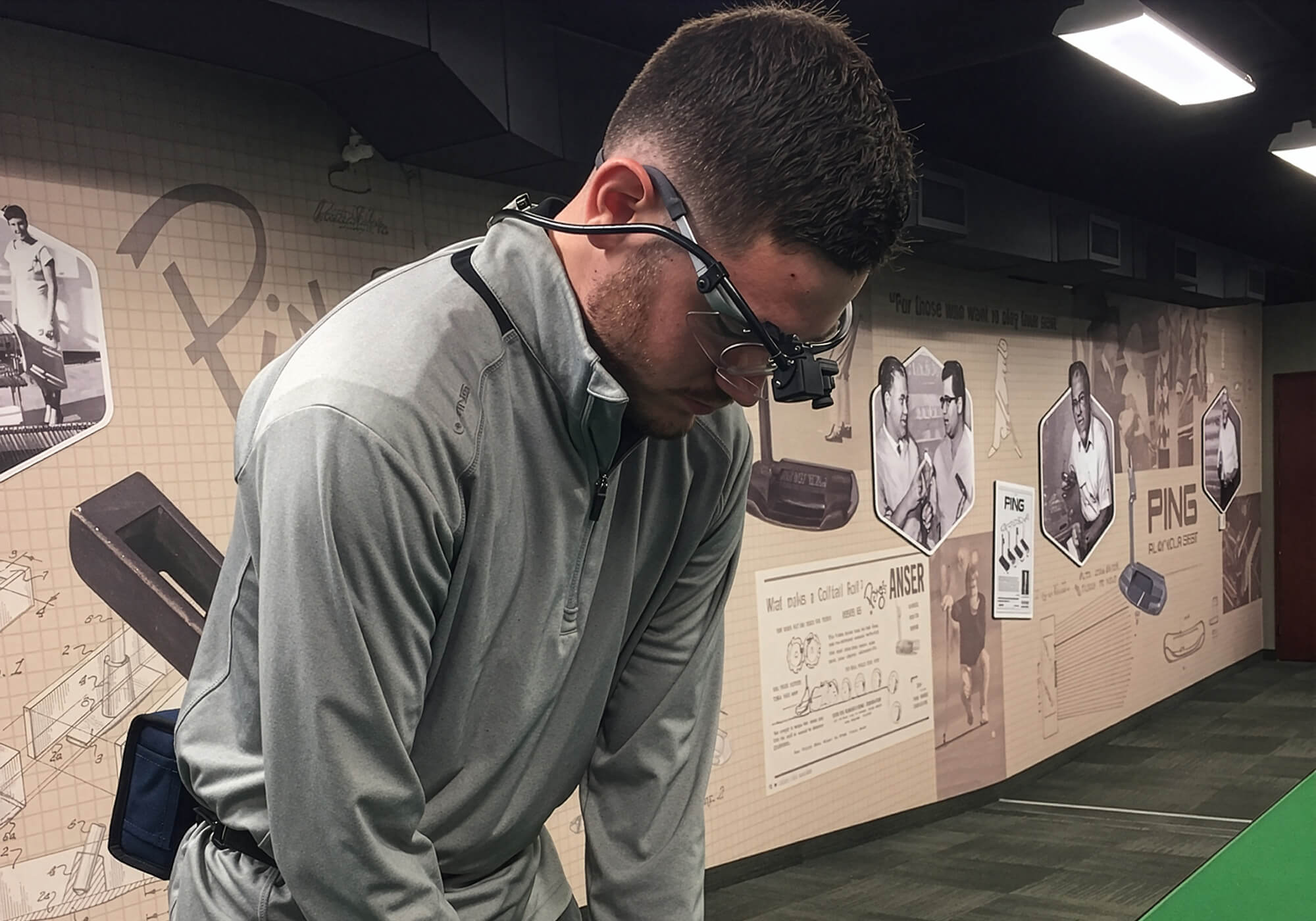

PING’s testing pool is essentially homegrown: about 150 to 200 workers, from scratch golfers to 20-handicaps. The group is segmented by enjoying means and product class. For better-player merchandise like Blueprint, the take a look at pool skews closely in direction of elite gamers, however throughout most classes, high-handicap golfers characteristic inside PING’s take a look at swimming pools.As a result of each tester’s movement is captured with PING’s FOCAL movement seize system, engineers can choose individuals by supply profile slightly than simply handicap. That very same knowledge additionally powers PING’s simulation fashions, making a uncommon suggestions loop between human testing and digital prediction.It’s one of the best of each worlds: engineers can validate simulations towards actual swings after which use these findings to refine each the membership and the mannequin. Henrikson calls it “closing the loop between curiosity and affirmation.”

Unconventional exams

PING’s testing tradition isn’t restricted to spreadsheets and robots. A few of its most attention-grabbing strategies border on absurd, even when they serve a objective.Henrikson remembers one of many extra notorious tales involving John A. Solheim. Early in a putter venture, PING wanted to verify the bond energy of a brand new insert. Fairly than defer to a lab take a look at, he requested an engineer to take it outdoors and hit it towards a concrete curb till it broke. It didn’t. The design handed.

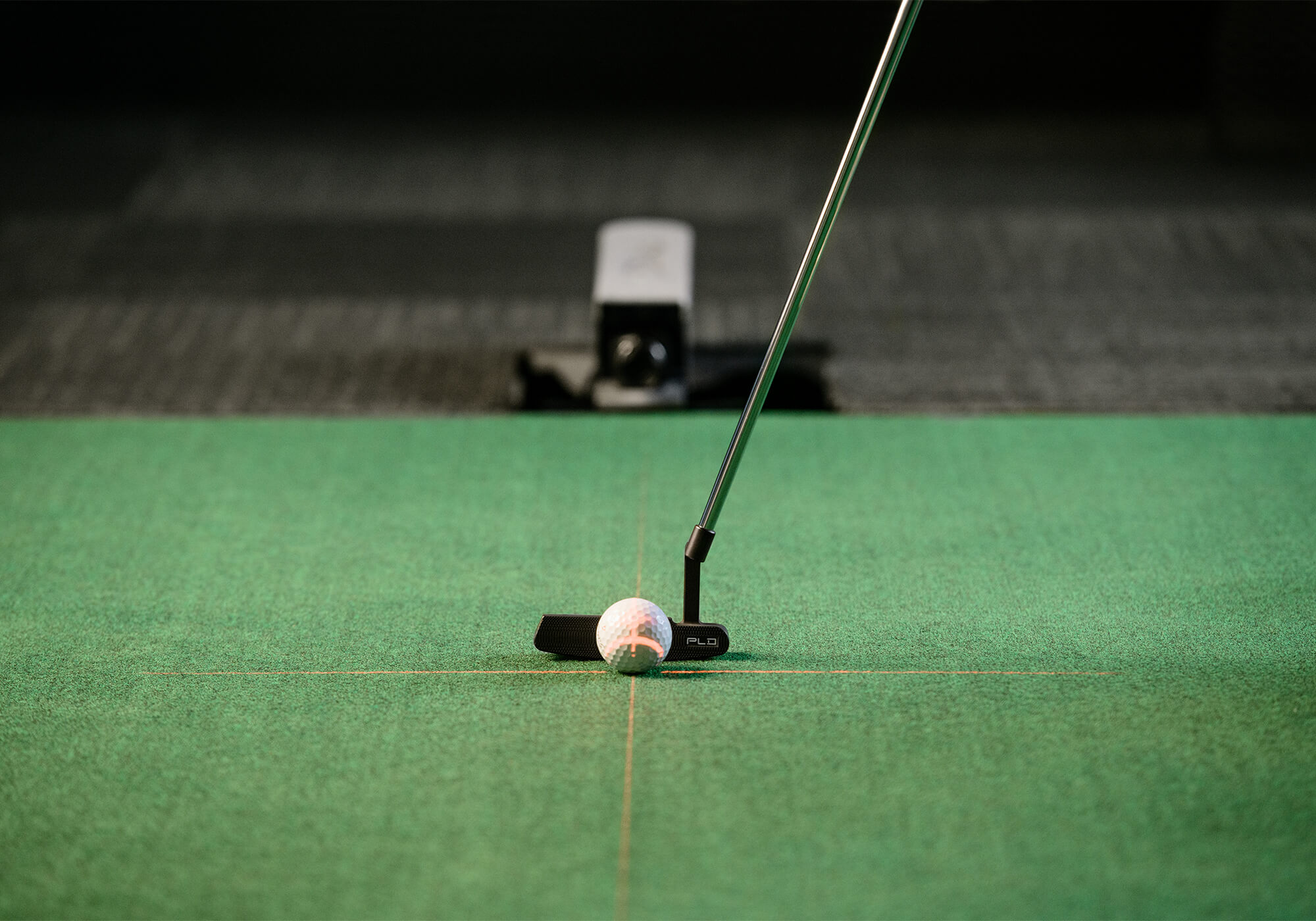

PING has used PING Man to tee off with a putter simply to verify epoxy integrity. Each new mannequin nonetheless has to outlive a 50-mph putter swing within the robotic lab.There’s additionally the waterproof-bag take a look at. As an alternative of counting on lab knowledge, engineers zip the pockets and put the bag underneath a bathe. If it leaks, it fails. It’s a reminder that exams don’t at all times should be complicated to be efficient.After which there are the inventive one-offs—eye-tracking research to measure how golfers visually course of alignment strains. That very same take a look at additionally led to PING altering the location of the shaft labels on its putters. A leaf-blower experiment was used to ensure headcovers gained’t blow away within the wind, and nothing beats an Arizona trunk-bake cycles to simulate warmth publicity.Every one is straightforward, sensible, and born from the identical philosophy: don’t assume, take a look at.

The position of the golf ball

The golf ball isn’t an adjunct at PING; it’s a part of the system.Trueblood says ball choice shapes each stage of testing, from drivers to putters. “Completely different balls make completely different sounds and clicks. Whether or not it’s a groove, an insert or a flat face, all of it performs into it.”That understanding runs deep. PING’s engineers account for the way the compression distinction between a Supersoft or a Professional V1 modifications influence acoustics and really feel for various swing speeds. These variations assist outline which sound profiles attraction to a given participant kind.And whereas PING doesn’t at present make golf balls, it research them relentlessly. The corporate’s Ballnamic venture grew out of this similar testing mindset: you possibly can’t separate membership efficiency from ball habits. Change the ball and you modify the membership.

Maintain your conclusions in an open hand

Henrikson laughs when he remembers how usually the info humbles them. “These experiences aid you understand how vital it’s to carry all of your conclusions with an open hand. We have now higher measurement expertise now, higher instruments, and there’s at all times one thing you didn’t contemplate.”He cites statistician George Field’s well-known quote: all fashions are mistaken; some are helpful. The trick, he says, is to make them much less mistaken yearly. That’s why PING habitually revisits its historical past. It’s not afraid to reexamine issues like how loft modifications have an effect on spin and launch on hybrids. PING’s first hybrid fashions date again to 2008; up to date variations adopted in 2015 and 2020. Every iteration makes the predictions extra correct however few issues are ever thought-about totally settled.

Generally issues change. Generally they don’t, however you don’t know that are which until you constantly take a look at.Trueblood says that angle goes all the way in which again to John A. “Once in a while, somebody is available in with a brand new concept and John says, ‘Yeah, we did that 25 years in the past.’ And he’s not dismissing you. It means the science nonetheless works.”

The method by no means ends

For PING, testing isn’t the tip of the method; it’s the suggestions loop that retains all the things sincere. Each delay, each mistaken flip, each “why didn’t that work?” second helps makes the subsequent reply higher, even when it’s seldom 100% definitive.

The instruments have modified however the intent hasn’t. Karsten’s wind tunnel on wheels has grow to be robots, movement seize and simulations, however the cause stays the identical: discover out what’s actual and do it once more tomorrow.

At PING, curiosity isn’t what occurs between initiatives. It’s the explanation there’s at all times a subsequent one.

The submit The Science Of Curiosity: Inside PING’s Relentless Testing Tradition appeared first on MyGolfSpy.