Query: What may very well be higher than having one set of 3D-printed irons in your lineup?

Reply: Why, three units of 3D-printed irons, after all.

COBRA is clearly all-in on 3D-printing expertise. By including two new iron units to enrich final yr’s marvelous 3DP Tour, COBRA feels it may well match anybody from a tour-level ball striker to a 25 or larger handicapper.

With three iron units.

I don’t care who you might be, that’s fairly spectacular.

If, after all, they’ll pull it off.

That mentioned, let’s get this Launch Get together began with a better have a look at the brand new COBRA 3DP MB and 3DP X irons. We predict COBRA may be on to one thing.

Why does COBRA 3D print irons?

3D printing isn’t new in golf. COBRA and others have been 3D printing playable prototypes for years. Nevertheless, COBRA is the primary – and nonetheless solely – OEM to commercialize the expertise. It began in 2020 with a 3D-printed putter. In 2024, COBRA proved the iron idea with two rounds of the limited-edition LIMIT3D irons. These irons morphed into final yr’s 3DP Tour. That iron had a blade-like footprint however with game-improvement-level forgiveness and playability.

(Sure, we all know AVODA made 3D-printed irons for Bryson. These, nevertheless, had been a one-off and had been 3D-printed as a result of it was the quickest approach to get Bryson a playable set of his curved-face irons in time for the 2024 Masters. AVODA doesn’t provide 3D-printed irons on the market and, so far as we all know, has no plans to.)

“3D printing permits us as designers and product creators to do issues we couldn’t do with regular forging or casting,” COBRA Innovation Director Ryan Roach tells MyGolfSpy. “It’s modified our mind-set as to what’s potential.”

By including a 3D-printed muscle-back and participant’s distance iron, COBRA believes it has the horses to carry 3DP expertise to tour gamers, 25 handicappers and everybody in between.

“It relies on a golfer’s wants,” says Roach. “However in speaking with our fitters, they are saying that with these three fashions, they’ll match anyone.”

Earlier than we proceed, we have to perceive what 3D printing permits COBRA to create. The iron itself doesn’t magically hit the ball higher or farther. What 3D printing does is permit COBRA to separate kind from perform.

“That separation permits us to get extra forgiveness into an iron with out sacrificing form or affect really feel to get there,” explains Roach. “We are able to have an effect on CG (middle of gravity) and MOI (second of inertia) with out having to vary the top form.”

Kind, perform and forgiveness

With conventional forgings or castings, kind follows perform. For an iron to have game-improvement-level forgiveness, the chassis have to be massive sufficient to accommodate a super-low middle of gravity and supply ample MOI for stability. There’s a motive, in spite of everything, why game-improvement irons look the best way they do.

“With 3D printing, we’re truly altering the inner kind to get the perform we would like,” says Roach. “The outer kind is one thing we will management individually.

“We are able to hone in on the texture we would like and the form we would like after which put within the forgiveness {that a} participant wants in a given class.”

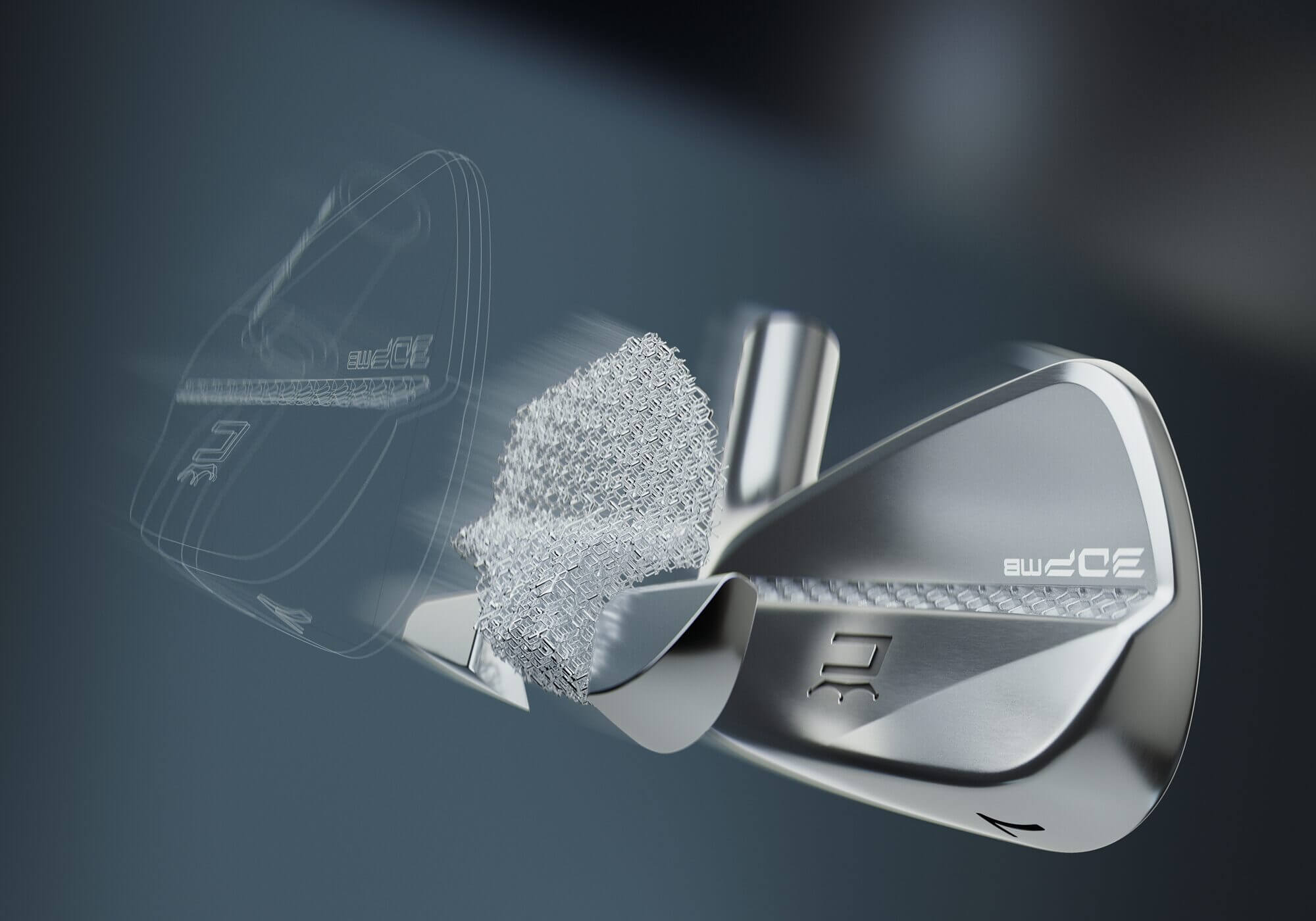

3D printing permits COBRA to create an inside that’s nearly unattainable to make with conventional manufacturing. The key sauce is a novel inside lattice construction that frees up an ungodly quantity of discretionary weight for such a small footprint.

For instance, the brand new 3DP MB muscle-back contains a thinner topline than COBRA’s cast KING MB, with an total chassis that’s smaller than the cast KING Tour. The inner lattice construction, nevertheless, frees up 66 grams of discretionary weight. That permits COBRA to maneuver 35 grams of tungsten weighting to the toe, 23 grams to the heel and eight grams into the hosel to extend forgiveness and decrease the CG.

For an iron that measurement, 66 grams is critical.

“We might have dropped the CG decrease with the MB, however we selected to not,” Roach explains. “MB gamers usually don’t have an issue launching the ball. They do need that further forgiveness together with sufficient spin, nevertheless, so we had been conscious to not drop the CG too low.”

The 3DP X, being extra of a participant’s distance iron, is all about getting the CG low for prime launch and low spin.

COBRA 3DP MB and 3DP X specifics

The COBRA 3DP MB relies on the prototype 3D-printed muscle-back (a single piece with out the lattice) that it made for Max Homa. The 3DP MB can be a single-piece blade however the inside lattice permits it to realize the forgiveness of COBRA’s KING Tec X game-improvement iron.

As talked about, the topline is barely thinner than COBRA’s cast KING MB blade however has a contact extra offset. The loft construction is what you’d contemplate conventional, with a 34-degree 7-iron.

“It has player-preferred shaping and really feel,” says Roach. “Nevertheless it’s playable for as much as a ten handicap, relying on why you’re a ten.”

Final yr’s 3DP Tour additionally has a head form smaller than the KING Tour however with much more discretionary weight and a decrease CG, it has the forgiveness of a game-improvement iron. Which makes one marvel, why did COBRA give us a 3DP X?

“Though the 3DP Tour could be very forgiving, larger handicaps would possibly wish to have a little bit bit larger face,” says Roach.

The 3DP X is about the identical measurement and form because the KING Tec-X however COBRA says it’s much more forgiving than the DS-ADAPT Max tremendous game-improvement iron.

Loftwise, the COBRA 3DP X, with a 29-degree 7-iron, is 2 levels weaker than the KING Tec-X. Consequently, the 3DP X delivers rather less ball velocity and carry distance. The launch angle is larger and the spin is about 800 rpm larger in comparison with the KING Tec-X in participant testing.

“The 3DP X offers extra launch, a steeper descent and extra playable distance,” says Roach, “however with significantly better really feel.”

About that really feel …

We wish to equate cast building with a mushy, buttery really feel. And whereas forging and supplies play a job, geometry performs a fair larger one.

“It’s very a lot shape-dependent,” Roach explains. “When you had a cast muscle-back and a solid muscle-back, it might be shocking how few of us might inform the distinction.”

COBRA’s 3DP irons are, after all, 3D printed utilizing a 316 stainless-steel powder that’s the consistency of powdered sugar. A single steel jet printer (the identical as utilized in aerospace manufacturing) can print as much as 32 heads over 24 hours. COBRA’s design software program not solely permits them to fine-tune the lattice construction but in addition lets them outline affect sound and affect vibration.

“The texture isn’t precisely the identical as a standard forging,” says Roach. “Some individuals say it feels higher, others say it’s not fairly the identical.”

My very own expertise final yr with the 3DP Tour irons bears that out. It wasn’t a standard cast sound and really feel. I wouldn’t categorize it as higher or worse, simply totally different on an analogous degree. Total, I discovered it pleasing.

What the lattice does do is that whether or not you’re speaking the 3DP MB, Tour or X, the sound and really feel will probably be in keeping with a cast muscle-back.

“The bottom line is the lattice community printed into the clubhead in the course of the printing course of,” Roach says. “With out 3D printing, you couldn’t get the efficiency we’re seeing with the texture we’re getting.”

Do we actually want 3D-printed irons?

The brief reply isn’t any. We didn’t want a perimeter-weighted putter, both, however that didn’t cease Karsten Solheim. Did we’d like a cast cavity-back? Nope, however Hogan created the Edge anyway.

We’ll say it once more so there’s no misunderstanding. A membership just like the COBRA DS-ADAPT Max offers you an identical forgiveness, distance and, doubtless, total efficiency because the 3DP X. There’s no magic in 3D printing apart from you will get all that forgiveness and efficiency in a a lot smaller chassis with significantly better really feel. Disrupting the established order, rewriting the foundations and opening up new prospects can’t probably be a nasty factor.

“There are 14 golf equipment in a golfer’s bag. We predict there’s a spot for 3D printing in each one in all them,” says Roach. “It might not occur tomorrow however that’s our imaginative and prescient for the place it will go.”

COBRA is assured that anybody from a tour participant to a 25 handicap will discover happiness with one in all its 3D-printed irons. Down the highway, nevertheless, 3D printing might change membership becoming as we all know it. Think about your club-by-club specs was ones and zeroes. A 3D printer whirrs into motion and, in a matter of hours, you may have a set of golf equipment 3D printed to your precise and particular wants.

Speak about bespoke.

“That’s nearer than it was 5 years in the past,” says Roach. “We’re doing that now for tour gamers. The writing on the wall says that’s one thing we will finally get out to customers. We simply don’t know when.”

COBRA 3DP MB and 3DP X specs, value and availability

Right here’s some information that ought to make you southpaws joyful. Because of 3D printing, the 3DP MB and 3DP X irons will probably be accessible in left- and right-handed fashions.

The COBRA 3DP MB will come inventory with the KBS $-Taper 110 because the inventory shaft. The 3DP X comes inventory with the KBS Tour Lite. Each will characteristic the Lamkin Crossline because the inventory grip. Each can have 4-irons and hole wedges accessible via customized order and the MB will provide a 3-iron as effectively.

As with the 3DP Tour irons, the brand new iron units received’t be what you name “bargain-basement.” Every will price $1,980 for a six-piece set.

They’re accessible for pre-sale beginning right now. They hit the shops on Jan. 9.

For extra info, hit up www.cobragolf.com.

The submit Why COBRA Is Doubling Down On 3D-Printed Irons appeared first on MyGolfSpy.